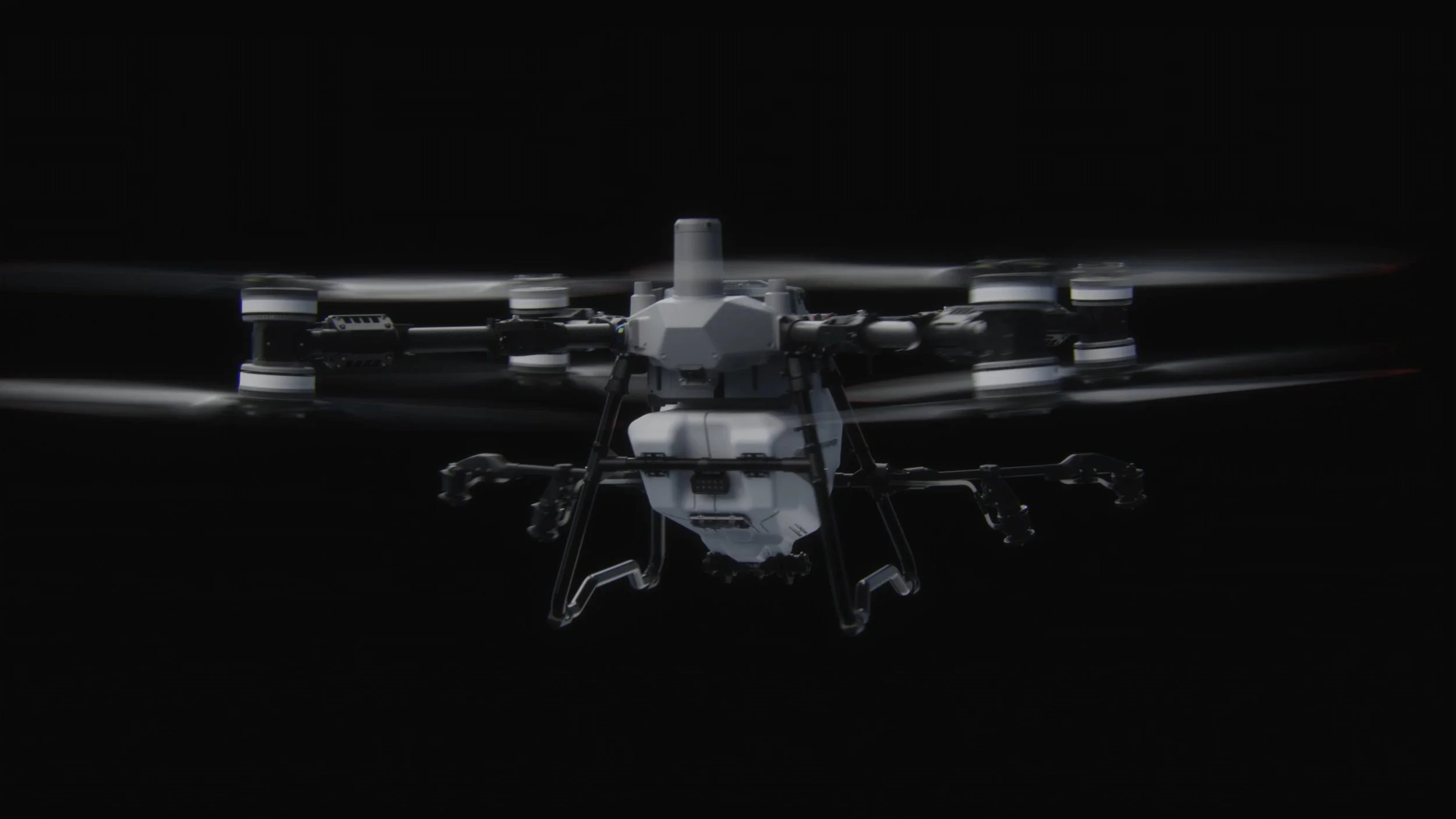

DJI AGRAS T100

Big Drone, Big Jobs.

The T100 Agricultural Drone, a groundbreaking creation twelve years in the making, boasts a maximum payload of 100 kg[1]. Its operational efficiency is doubled, supporting multiple application scenarios, including spraying, spreading, and lifting tasks. Featuring industry-leading safety systems[2] and advanced algorithms, it delivers unparalleled safety performance and an intelligent operational experience.

100 L Spraying Tank, 40 L/min Flow Rate

20 m/s Max Operation Speed

150 L Spreading Tank, 400 kg/min Flow Rate

100 kg Lifting

LiDAR + Penta-Vision System + Millimeter-Wave Radar

Ultra-Fast Charging

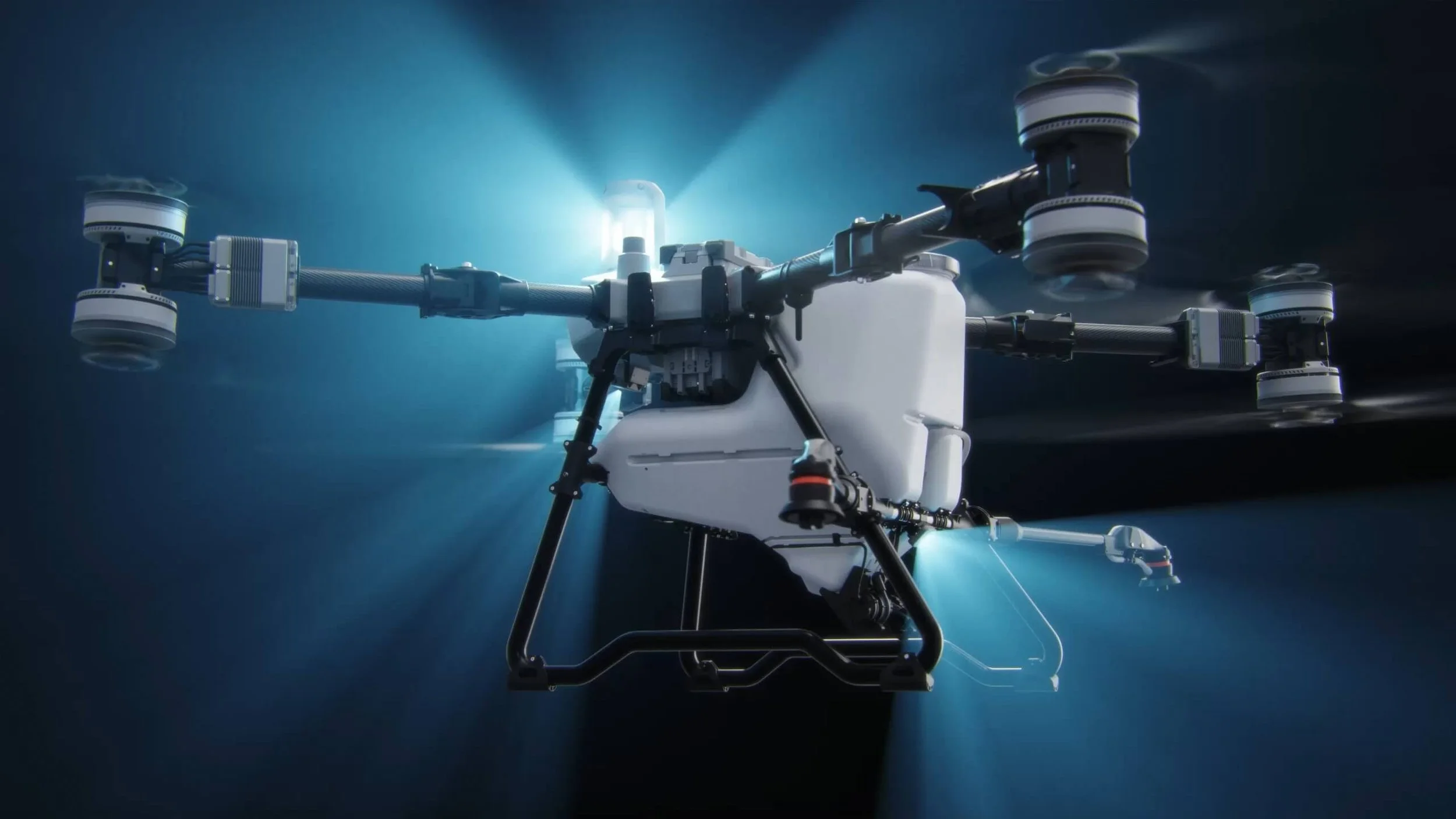

Spraying System

Efficient operation,

Outstanding performance.

The T100 comes equipped with a 100 L tank and dual atomizing centrifugal sprinklers, enabling faster flight speeds, wider spray coverage, and higher operation efficiency for large-scale field applications. Orchard users can choose an optional mist sprinkler set, which upgrades flow rates and atomization effects to penetrate dense canopies and reach the undersides of leaves on tall, thickly-canopied trees, ensuring outstanding versatility and performance across various agricultural tasks.

Field Operations

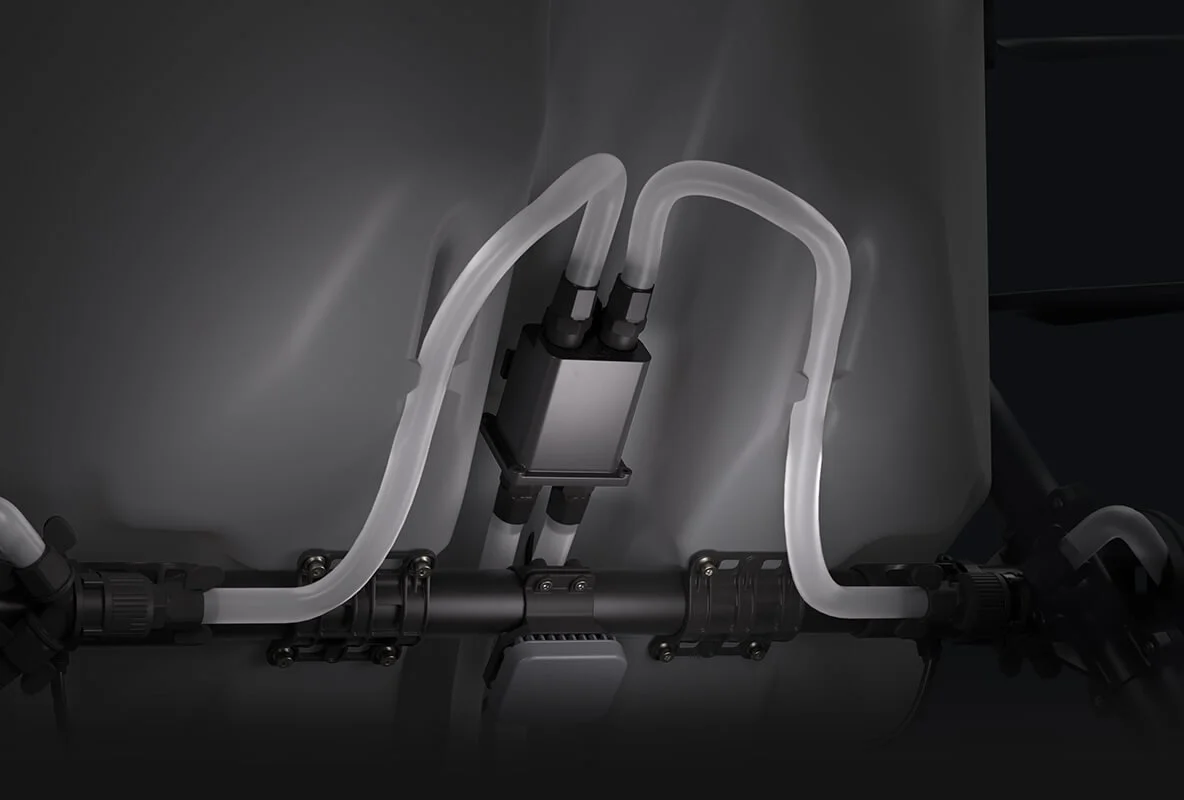

Water-Cooled Mist Sprinkler(Optional)

Fine droplets as small as 50 μm[23] penetrate canopies for comprehensive leaf coverage. A new liquid flow path helps dissipate dual centrifugal motor heat for durability and longevity.

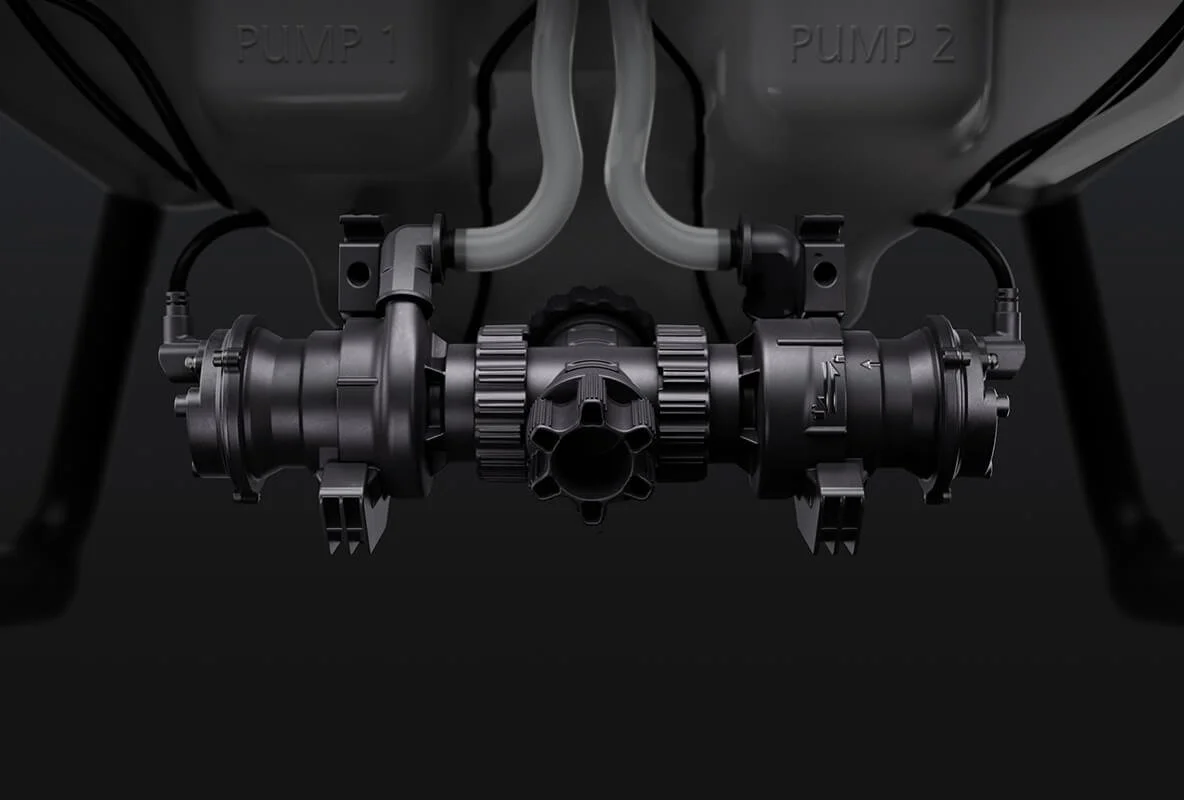

Magnetic Drive Impeller Pumps

Corrosion-resistant, stable, and reliable, an optimized impeller structure and increased chamber volume meet the high flow demands of orchard scenarios.

Orchard Operations

Dual Atomization Centrifugal Sprinkler

New flow channel design, particle size range 50-500 μm[9], suitable for most operational scenarios.

Rear Four Sprinklers Array

It expands the spray width for orchard operations while maintaining uniform coverage. It also minimizes visual interference from mist, enhancing operational reliability and precision.

Dual-Channel Electromagnetic Flow Meter

Real-time precise flow detection and dynamic control ensures high-precision operations. It avoids direct contact with the liquid, preventing corrosion and enhancing durability.

Spreading System

Bigger Loads, Faster Flow, Better Efficiency

The T100 Spreading System has been fully upgraded, with double the load capacity, and a 270%[7] increase in flow rate. Equipped with a brand-new screw feeder, it is suitable for various granulars and can handle spreading scenarios in large fields, orchards, aquaculture, and more.

Extra-Large Feeder

Suitable for granulars such as fertilizers, wheat seeds, granular fungicides, feed, etc.

Recommended application rate: 75-750 kg per hectare.

Recommended particle size: 0.5-10 mm

Four Feeder Types

Supports four interchangeable feeder sizes for precise flow and greater adaptability[11] across seeding, fertilizing, and feeding.

Large Feeder (Optional)

Suitable for granulars such as rice seeds, cover crop seeds, etc.

Recommended application rate: 75-270 kg per hectare.

Recommended particle size: 4-10 mm

Medium Feeder

Suitable for granulars such as rice seeds.

Recommended application rate: 22.5-120 kg per hectare.

Recommended particle size: 4-6 mm

Small Feeder (Optional)

Suitable for granulars such as rapeseed, granular herbicides, grass seeds, granular insecticides, etc.

Recommended application rate: 3-22.5 kg per hectare.

Recommended particle size: 0.5-4 mm.

Safety System

Industry-Leading Safety System[2], Safer With Every Flight

Omnidirectional Sensing, Precise Obstacle Detection

T100 is equipped with advanced technologies, including a new LiDAR, millimeter-wave radar, and a Penta-Vision system[12]. These features enable comprehensive environmental awareness, allowing for precise obstacle detection.

LiDAR

Capable of capturing dense spatial point cloud up to 300,000 points per second, providing a detailed view of complex terrains.

Millimeter-Wave Radar

The front radar performs 5,000 vertical airspace scans per second combined with 360° horizontal mechanical rotation scanning, along with a rear radar[12] offering a more comprehensive detection range.

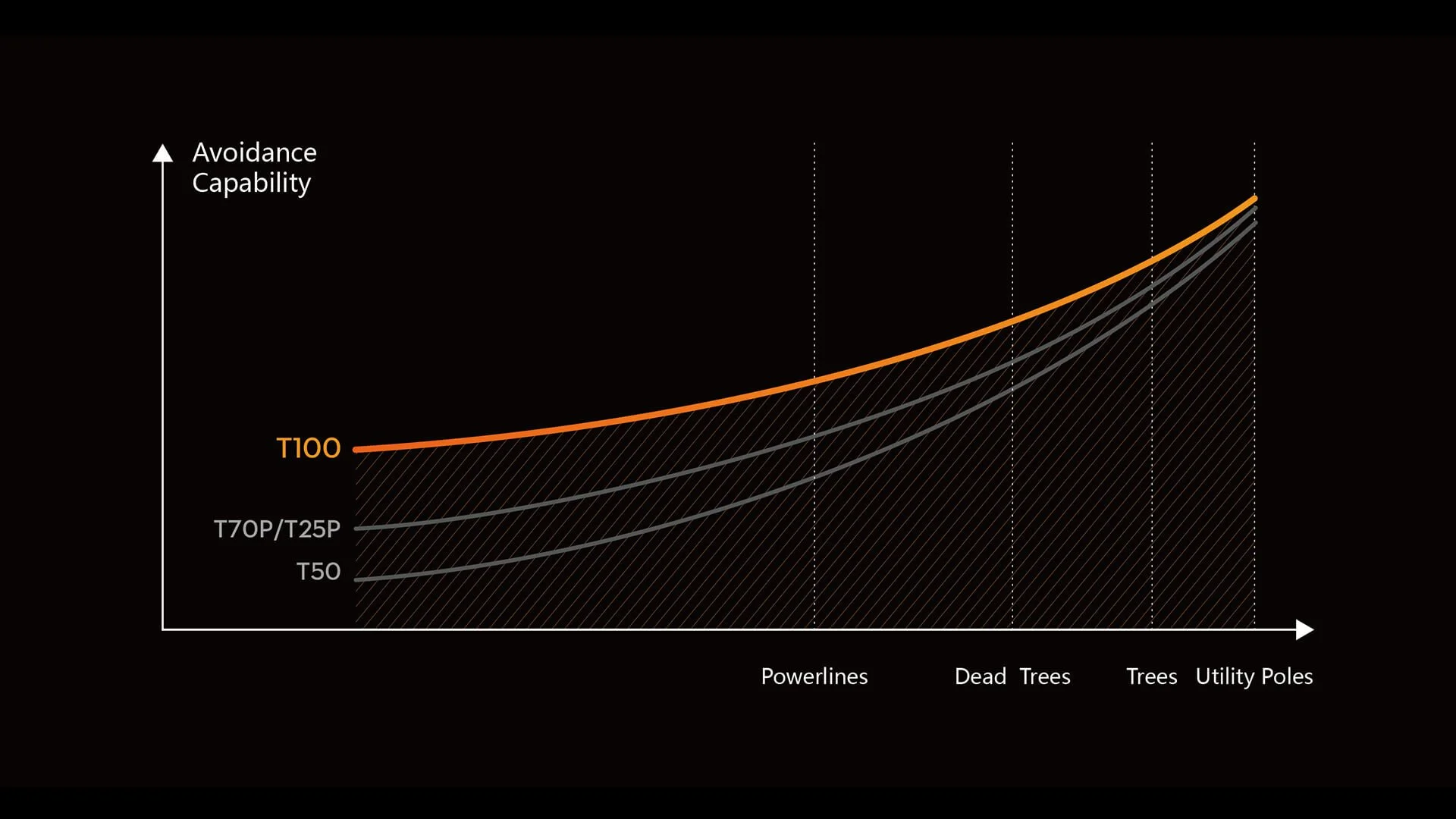

Enhanced Obstacle Avoidance Capabilities

With advanced multi-sensor fusion and upgraded algorithms, the T100 achieves a higher success rate in avoiding various obstacles. Its precision in detecting smaller obstacles is significantly improved, ensuring safer and more reliable operations[2].

Lift System

Your Transport Assistant

The T100 transforms into a transport solution. With a lifting maximum capacity of 100 kg[5]. Features like auto balance control , weight detection, and automatic navigation to loading and unloading points make it adaptable to various agricultural transport scenarios.

Solar Panels

Fruits

Saplings

Building Materials

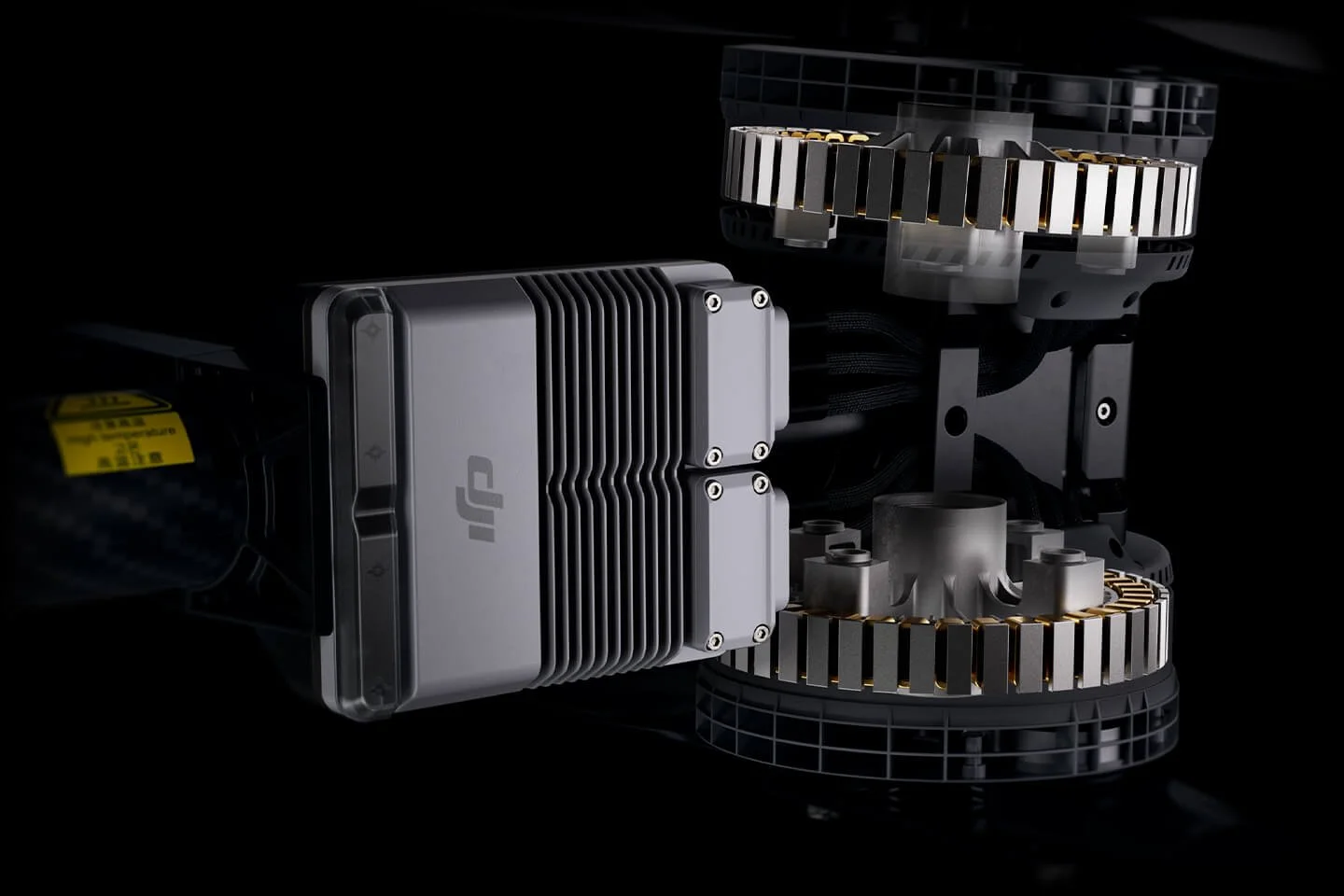

Propulsion System

Powerful, Efficient, Reliable Under High Temperatures

The coaxial dual-rotor design, paired with carbon fiber propellers, delivers a comprehensive upgrade in performance, efficiency, and safety redundancy.

Coaxial Dual-Rotor

62-Inch Carbon Fiber Propellers

Carbon fiber propellers offer greater rigidity and lighter weight, resisting deformation even at high temperatures. With optimized airfoil and increased diameter, efficiency is improved by 32%[7].

Motors and ESCs

Larger motors, more torque. 420A electronic speed controllers ensure stable and reliable operation, delivering faster response times.

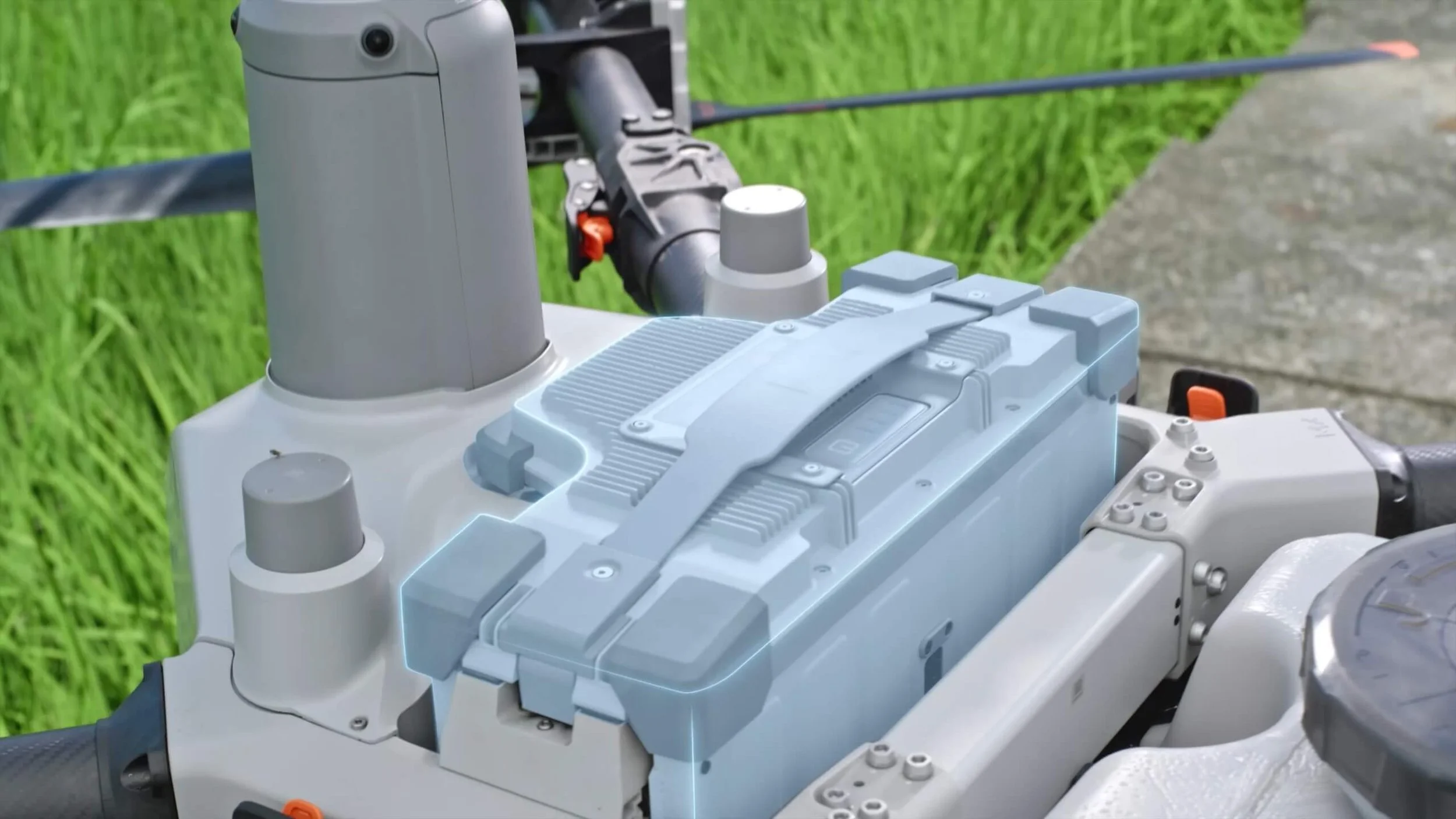

Power System

Ultra-Fast Charging, Energy-Efficient Design

*The product is only available in certain countries. The appearance of the product is subject to the actual product. For details, please contact your local dealer.

[1] Measured at sea level, DJI Agriculture App intelligently recommends the appropriate loading weight based on the current status of the aircraft, environmental conditions, and operational tasks. Users are advised not to exceed the recommended maximum weight of the loaded granulars, may impact flight safety.

[2] The effective sensing range and its ability to avoid and bypass obstacles will vary depending on the ambient light, rain, fog, and the material, position, shape, and other properties of the obstacles. Downward sensing is used to assist in Terrain Following flight and altitude stabilization, while other directions assist with obstacle avoidance. Any collision between the bottom of the aircraft and obstacles shall be the customer's responsibility. In scenarios without linear obstacles, if a collision occurs at speeds up to 13.8 m/s resulting in aircraft damage, responsibility can be determined through log analysis, and the aircraft may be eligible for free warranty if non-human causes are identified. If there are linear obstacles like wires or guy wires on utility poles, please mark them as obstacles; otherwise, failure to bypass them will be the customer's responsibility.

- Note 1. Downward sensing assists in Terrain Following flight. If the bottom collides with obstacles, it is considered user responsibility. - Note 2. Due to limitations in safety system performance, the aircraft cannot automatically avoid moving objects, and accidents of this nature will be attributed to user responsibility.

[3] Different granular densities vary, and the maximum load should not exceed 100 kilograms.

[4] Measured with compound fertilizer. The maximum flow rate may vary due to differences in granule size, density, and surface smoothness of different fertilizers.

[5] A weight of 100 kg is measured below the triaxial force sensor (including the weight of the sling, and hook). Data was measured at sea level. The DJI Agras app will recommend the payload weight according to the current status and surroundings of the aircraft. When adding materials, the maximum weight should not exceed the recommended value, otherwise flight safety may be compromised. Users must comply with local regulations during operation.

[6] The actual operation speed of the drone is related to the terrain slope; the steeper the slope, the lower the operation speed. The maximum operating speed varies by country and operational mode, and is subject to local regulations and the actual firmware version.

[7] Compared to the Agras T50 drone and its supporting equipment. Test results may vary based on different testing conditions.