Hull Inspection

Underwater drones replace frogmen to complete general visual inspection tasks, reducing operating costs and underwater operation risks. They also assist in developing better operational and maintenance schedules, improving hull safety and fuel efficiency.

Easy to use and high efficiency

Plug and play, a single person can complete the deployment in 5 minutes, and can start the inspection task without waiting for the frogman.

Low cost

Replaces frogmen to inspect the hull, which can be operated by a single person. Avoids the reduction of operating revenue caused by the downtime during inspection, which greatly reduces costs.

One-click report generation

Generates a hull inspection report with one click after the inspection.

Work all day

Equipped with a spare battery pack or powered by AC power, underwater drones can work continuously for a long time and improve the inspection efficiency.

Application scenarios

Check the antifouling paint

Check the damage degree of antifouling paint on the side and bottom of the ship, and decide whether it is necessary to arrange the service company to repair the paint.

Check the marine life

Check the marine growth on the hull side and decide whether it is necessary to arrange the service company to clean it up.

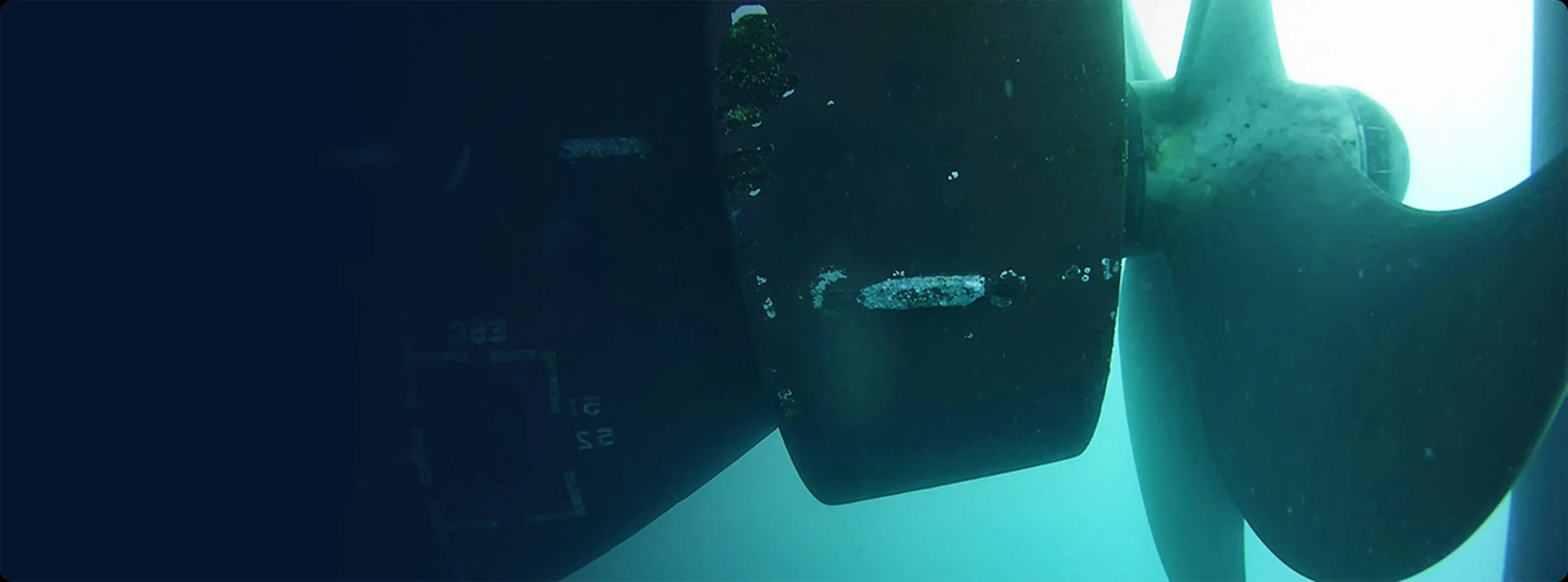

Check critical parts for damage

When the ship berths at the port/anchorage, check whether the key parts such as propeller/rudder and sea chest are damaged.

Check for impact damage

When a ship collides at sea, check whether the bow or stern of the ship is damaged by collision.